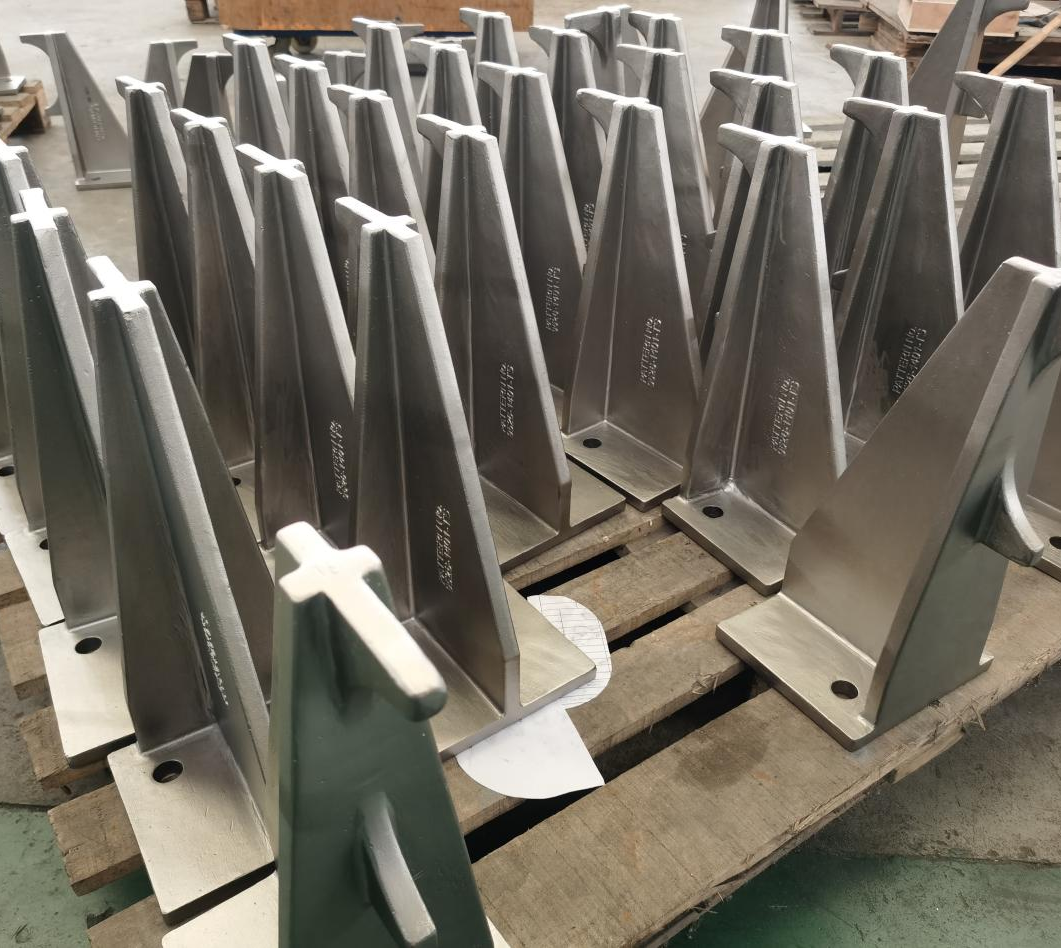

Heavy-Duty CASTED TUBE SUPPORT

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean,Land,Air |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean,Land,Air |

Brand: Simcan

| Selling Units | : | Piece/Pieces |

CASTED TUBE SUPPORT

The casted tube support is key component for direct fired heater for supporting tubes including extend surface tubes both in radiant section and convection section.

The casted tube support is casted with high chromium and nickle composition for high temperature and corrosive flue gas operating case.

In the intricate world of industrial machinery and systems, casted tube supports stand as unsung heroes, ensuring stability and efficiency across a broad spectrum of applications. From heat exchangers to boilers, and chemical processing equipment, these precisely engineered supports play a pivotal role. This article explores the importance of casted tube supports, material considerations, and future developments in the field.

Casted tube supports are crucial for maintaining the integrity and performance of industrial piping and tubing systems. They provide essential support, preventing vibration and wear due to thermal expansion and mechanical forces. In high-pressure and high-temperature environments, the stability offered by these supports is not just crucial for efficiency but paramount for safety as well.

The choice of material for casted tube supports is a critical decision that impacts the durability, performance, and safety of the entire system. Common materials include: 19Cr-9Ni,25Cr-12Ni,25Cr-20Ni,50Cr-50Ni-Nb

The selection process considers factors like temperature, pressure, chemical exposure, and the specific requirements of the application to ensure optimal performance and longevity.

Technological advancements have significantly influenced the design and manufacturing processes of casted tube supports. Modern computational tools and simulation software enable engineers to test and validate designs before production, reducing the risk of failure and improving efficiency. Additionally, innovations such as 3D printing offer new possibilities for producing complex shapes and custom designs, expanding the applications and effectiveness of casted tube supports.

As the push for renewable energy and clean technology grows, the applications for casted tube supports are set to broaden. Developments in materials and manufacturing techniques promise more durable, efficient, and environmentally friendly supports. Integration of smart monitoring technologies could revolutionize maintenance practices, reducing operational costs and improving reliability.

Casted tube supports are indispensable components that ensure the efficient operation of industrial equipment. Through ongoing innovation in technology and materials research, these crucial support structures will continue to play a vital role in modern industry, enhancing safety, efficiency, and sustainability.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.