Aluminum Fin Tube for Air Cooled Heat Exchanger

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean |

| Port: | Shanghai |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean |

| Port: | Shanghai |

| Selling Units | : | Piece/Pieces |

Aluminum Fin Tube For Air Cooled Heat Exchanger

Air Cooled Heat Exchanger is also called as Fin Fan Cooler or Air Fin Cooler due to it consists of two two major parts which are fin tube bundles and fans. Simcan is leading manufacturer of the aluminum fin tubes used for air cooled heat exchangers.

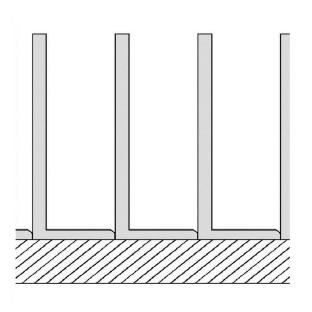

“L” Fin Tube

The strip material(aluminum or copper ) is controlled to deform under tension so that the optimum contact pressure at the bottom of the fins is applied to the base tube to maximize heat transfer performance. The L foot of the fin greatly enhances the corrosion resistance of the base pipe.“L” Fin Tube is suitable for high working temperatures up to 150°C.

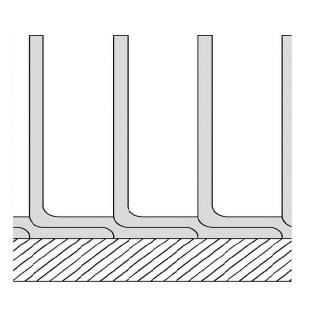

“LL” Fin Tube

Manufactured in the same way as the “L” Finned Tube type except that the fin foot is overlapped to completely enclose the base tube thereby giving excellent corrosion resistance. This type of finned tube is often used as an alternative to the more expensive extruded type fin in corrosive environments. “LL” Fin Tube is suitable for high working temperatures up to 180°C.

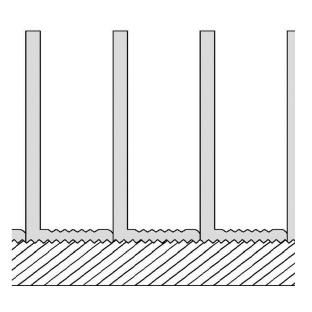

“KL” FINNED TUBE

“KL”Finned Tube is also called “knurled finned tube”. Before fin winding, the knurling is performed on the outside surface of the base tube. After winding, the root of the L foot of aluminum fin is subjected to secondary knurling to strengthen the bond between the fin and tube. Knurling and winding are performed simultaneously. Contact area increased by about 50%. “KL” Fin Tube is suitable for high working temperatures up to 260°C.

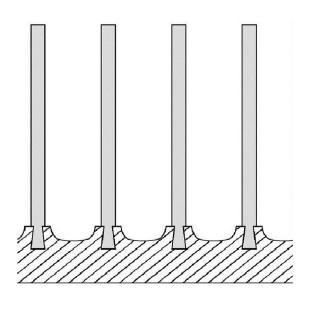

“G” Embedded Finned Tube

“G” Embedded Finned Tube, also known as G-fins (grooved fins), is widely used throughout the world. The fin strips are mechanically forged into the machined grooves and are securely locked into place by back filling with the base tube material. This ensures a mechanical bond with the tube and have negligible fin bonding and thermal cycling degradation. Typically, the fins are made of aluminum or copper. “G” Embedded Finned Tube is suitable for high working temperatures up to 400°C.

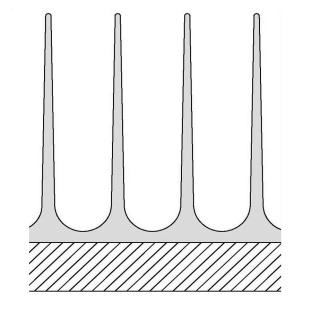

EXTRUDED FIN TUBE

Aluminum Extruded Fin Tube is formed from a bi-metallic tube. Consisting of an aluminum outer core and an inner tube(steel, copper or titanium etc.) as a mandrel. Outer core is compressed to fins on its outside surface through the cavity formed by the groove and the inner tube by the rolling blade. The finned tube produced by this method provide an integral fin, so there is no contact thermal resistance loss, and the heat transfer efficiency is high. Compared with the welding process, the three-roll cross-rolling(extruding) process has the advantages of high production efficiency, low consumption of raw materials, and high heat exchange rate.Maximum operating temperature for Extruded Fin Tube is 290°c.

DIMENSION AND MATERIAL

The following table shows Simcan’s manufacturing capabilities for Aluminum Fin Tube For Air Cooled Heat Exchanger:

| Tube O.D.: | 19.0 to 51.0 (mm) | 3/8” to 2” |

| Tube Wall Thk.: | L, LL, KL: 1.65 to 3.0 (mm) G: 2.11 to 3.5 (mm) | L, LL, KL: 0.065” to 0.118” G: 0.083” to 0.138” |

| Tube Length: | ≤ 18,500 (mm) | ≤ 60.8 ft |

| Fin Thk.: | 0.3 to 0.5 (mm) | 0.012” to 0.02” |

| Fin Height: | 10.0 to 16.0 (mm) | 0.394” to 0.630” |

| Fin Pitch: | 100 to 433 FPM | 3 to 11 FPI |

| Fin Type: | L, LL, KL, G | |

| Fin Material: | Aluminum (most common grade: Alu.1100, Alu.1060, Alu.6063 ) Copper | |

| Tube Material: | C.S. (most common grade: A179, A192,SA210 Gr A1/C,A106 Gr B ) S.S. (most common grade: TP304, 316) Copper (most common grade: UNS12200,14200, 70600, CuNi70/30, CuNi 90/10 ) Titanium (most common grade: B338 Gr 2) | |

| * This table is used as a general guide to our capabilities, please call us for any other customized cases. | ||

PRODUCTION CAPACITY

Simcan has Total seven(7) Aluminum Fin Tube For Air Cooled Heat Exchanger finning lines, monthly production capacity is 200,000 meters in total.

APPLICAITONS

Simcan's Aluminum Fin Tube For Air Cooled Heat Exchanger are mainly used in air cooled heat exchangers (fin fan cooler, air fin ) or air heaters in petrochemical, power generation, paper, tobacco, building heating system, air conditioning and food industries.

FAQ

Q1.What is the referenced codes and standards?

API661

Material Requisition, drawings or Technical Agreement

Q2.How do you pack the products

A:Each package is designed and made according to seaworthy packing standard and clients’ handling and lifting capability.

Finned tubes will be packed into steel frameworks and wrapped with weather proof PE film and plywood board covering up. In addition, each row of finned tubes will be isolated from adjacent with EPE(Expandable Polyethylene) foam to prevent rigid impact during transportation. For all exporting packages, we only use plywood instead of wood for fumigation free purpose.

Q3:How do you guarantee the quality?

A:we are ISO certified company and we maintain strict controls according to our specific written procedures and client specifications during all phases of manufacturing of our products ensuring full materials traceability and top quality. Besides, inspection activities carried out by world reputable third party such as TÜV, BV, SGS, Lloyd's, ABS, Intertek(Moody) etc. is available on call.

Q4:Do you have design capability?

A:Yes, we could develop the shop drawings and submit for clients’ approval.

Q4:How do you handle the documentation?

A:As a professional supplier, Simcan does not only manufactures products but also has strong capability on preparing and submitting documents as listed below but not limited to:

Before Fabrication

Design and Fabrication Schedule

Drawings and data

Fabrication Procedures including WPS, PQR

Inspection and Test Plan (ITP)

During Fabrication

Daily, weekly or monthly progress report

After Fabrication

A complete set of final archive including:

Raw Material Mill Certificates

Product Conformity Certificates

Inspection Reports including Material Receipt Inspection Report, Test Report etc.

Packing List and Proforma Invoice

Certificate of Origin or any other documentation mandatory for clients’ customs clearance or tax preference

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.