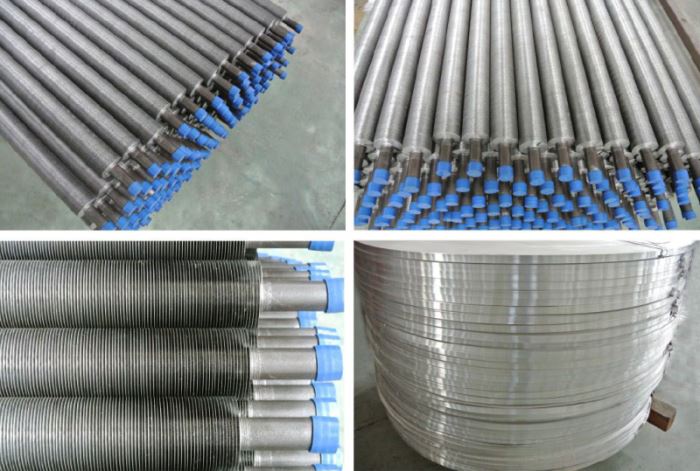

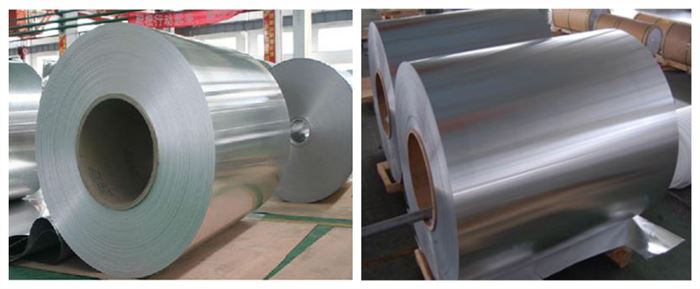

1060 Aluminum Strip for LL KL Fin Tube

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

| Selling Units | : | Piece/Pieces |

1060 ALUMINUN STRIP FOR L,LL,KL,G Fin Tube

The 1060 aluminum fin strip has an aluminum content of 99.6% and is also called a pure aluminum sheet. It belongs to a commonly used series in the aluminum strip family. The most commonly used series of this series of aluminum plates, the production process is relatively simple, the technology is relatively mature, and the price has a huge advantage over other high-grade alloy aluminum plates. Has good elongation and tensile strength, can fully meet the conventional processing requirements (stamping, drawing) high moldability, industrial pure aluminum, with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength , heat treatment can not enhance the machinability is not good; gas welding, hydrogen atom welding and contact welding, not easy to braze; easy to withstand various pressure processing and extension, bending.

1060 aluminum chemical composition:

Silicon Si: 0.25; iron Fe: 0.35; copper Cu: 0.05; manganese Mn: 0.03; magnesium Mg: 0.03; zinc Zn: 0.05; titanium Ti: 0.03; vanadium V: 0.05; aluminum Al: 99.6

1060 aluminum mechanical properties:

Tensile strength σb (MPa) ≥75

Conditional yield strength σ0.2 (MPa)≥35

Sample size: all wall thickness

Note: Longitudinal mechanical properties of pipe at room temperature

1060 aluminum heat treatment process:

Rapid annealing: heating temperature 350~410 °C; with the effective thickness of the material, the holding time is between 30~120min; air or water cooling.

High temperature annealing: heating temperature 350~500 °C; when the finished product thickness is ≥6mm, the holding time is 10~30min, <6mm, heat penetration; air cooling.

Low temperature annealing: heating temperature 150~250 °C; holding time is 2~3h; air or water cooling.

Application Size:

| Fin Thk.: | 0.3 to 0.5 (mm) | 0.012” to 0.02” |

| Fin Height: | 10.0 to 16.0 (mm) | 0.394” to 0.630” |

| Fin Material: | Aluminum (most common grade: Alu.1100, Alu.1060, Alu.6063 ) | |

| * This table is used as a general guide to our capabilities, please call us for any other customized cases. | ||

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.