Steel Integral Finned Tubes

Get Latest Price| Min. Order: | 1 Piece/Pieces |

| Selling Units | : | Piece/Pieces |

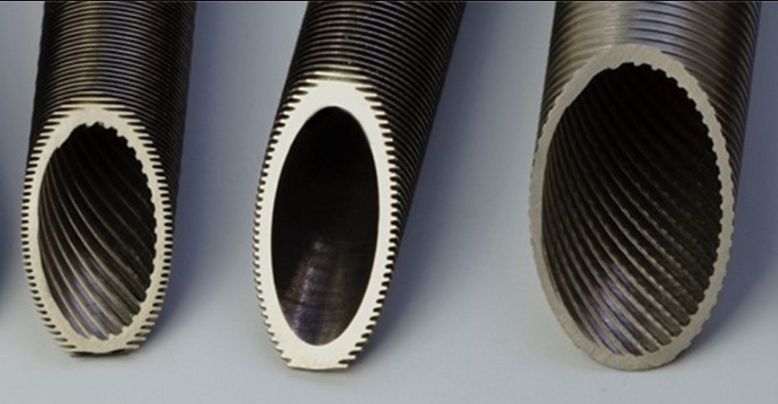

Steel Integral Finned Tube

The Steel Integral Finned Tube fins are rolled out from the wall of the tubes and hence are integral with the tube. As the fins are formed from the base tube by rolling out material from its wall, the wall thickness under the finned section is reduced compared to the wall thickness at plain ends. These fin tubes can be manufactured from most tubular materials and the hardness of the material usually determines the finning code or fin profile. The harder materials such as Nickel Alloys, Stainless Steel, Titanium are supplied with higher density (i.e. 26, 28, 30 FPI). This shallow profile reduces the work hardening of the material and helps to eliminate the possibility of root fin cracking.

Whereas, softer materials like Carbon Steel, Copper, and Copper Alloys are supplied with deeper profile giving a lower fin density (i.e. 16 or 19 FPI). These tubes can also be supplied with intermediate plain landing as well as U bent, where U bend portion can be finned or un-finned.

WHY USE FINNED TUBES

Long service life, more than three times than welded or wound type finned tubes.

It is produced by hot rolling process, which improves the density, yield strength, tensile strength and wear resistance of metal structures.

No thermal contact resistance loss, the heat exchange efficiency is maximized

Suitable for high temperature and severe operating cases, the heat transfer stability is much solid than other type finned tubes which insufficient contacts between fins and tube surface or fin falling off may happen.

DIMENSION AND MATERIAL

The following table shows Simcan’s manufacturing capabilities for Steel Integral Finned Tube:

| Tube O.D.: | 12.7 to 31.75 (mm) | 1/4” to 1 1/4”(NPS) |

| Tube Wall Thk.: | 1.65 to 3.0 (mm) | 0.065” to 0.118” |

| Tube Length: | ≤ 18,500 (mm) | ≤ 60.7 ft |

| Fin Thk.: | 0.3 to 0.5 (mm) | 0.0118” to 0.0197” |

| Fin Height: | 0.9 to 1.3 (mm) | 0.0354” to 0.0512” |

| Fin Pitch: | 666 to 1111 FPM | 16 to 30 FPI |

| Fin Type: | Integral Low Fin | |

| C.S. S.S. A.S. Titanium | ||

| * This table is used as a general guide to our capabilities, please call us for any other customized cases. | ||

PRODUCTION CAPACITY

Total four (4) Steel Integral Finned Tube finning lines, monthly production capacity is 80,000 meters in total.

APPLICAITONS

Simcan's Steel Integral Finned Tube are generally used in petrochemical industry for high temperature and severe operating cases.

FAQ

Q1.What is the referenced codes and standards?

A:We manufacture according to requirements specified in Material Requisition, drawings or Technical Agreement

Q2.How do you pack the products

A: Each package is designed and made according to seaworthy packing standard and clients’ handling and lifting capability.

Finned tubes will be packed into steel frameworks and wrapped with weather proof PE film and plywood board covering up. In addition, each row of finned tubes will be isolated from adjacent with plywood bars to prevent rigid impact during transportation. For all exporting packages, we only use plywood instead of wood for fumigation free purpose.

Q3:How do you guarantee the quality?

A:We are ISO certified company and we maintain strict controls according to our specific written procedures and client specifications during all phases of manufacturing of our products ensuring full materials traceability and top quality. Besides, inspection activities carried out by world reputable third party such as TÜV, BV, SGS, Lloyd's, ABS, Intertek(Moody) etc. is available on call.

Q4:Do you have design capability?

A:Yes, we could develop the shop drawings and submit for clients’ approval.

Q4:How do you handle the documentation?

A:As a professional supplier, Simcan does not only manufactures products but also has strong capability on preparing and submitting documents as listed below but not limited to:

Before Fabrication

Design and Fabrication Schedule

Drawings and data

Fabrication Procedures including WPS, PQR

Inspection and Test Plan (ITP)

During Fabrication

Daily, weekly or monthly progress report

After Fabrication

A complete set of final archive including:

Raw Material Mill Certificates

Product Conformity Certificates

Inspection Reports including Material Receipt Inspection Report, Test Report etc.

Packing List and Proforma Invoice

Certificate of Origin or any other documentation mandatory for clients’ customs clearance or tax preference

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.